Грешка във формата на имейла

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Новини

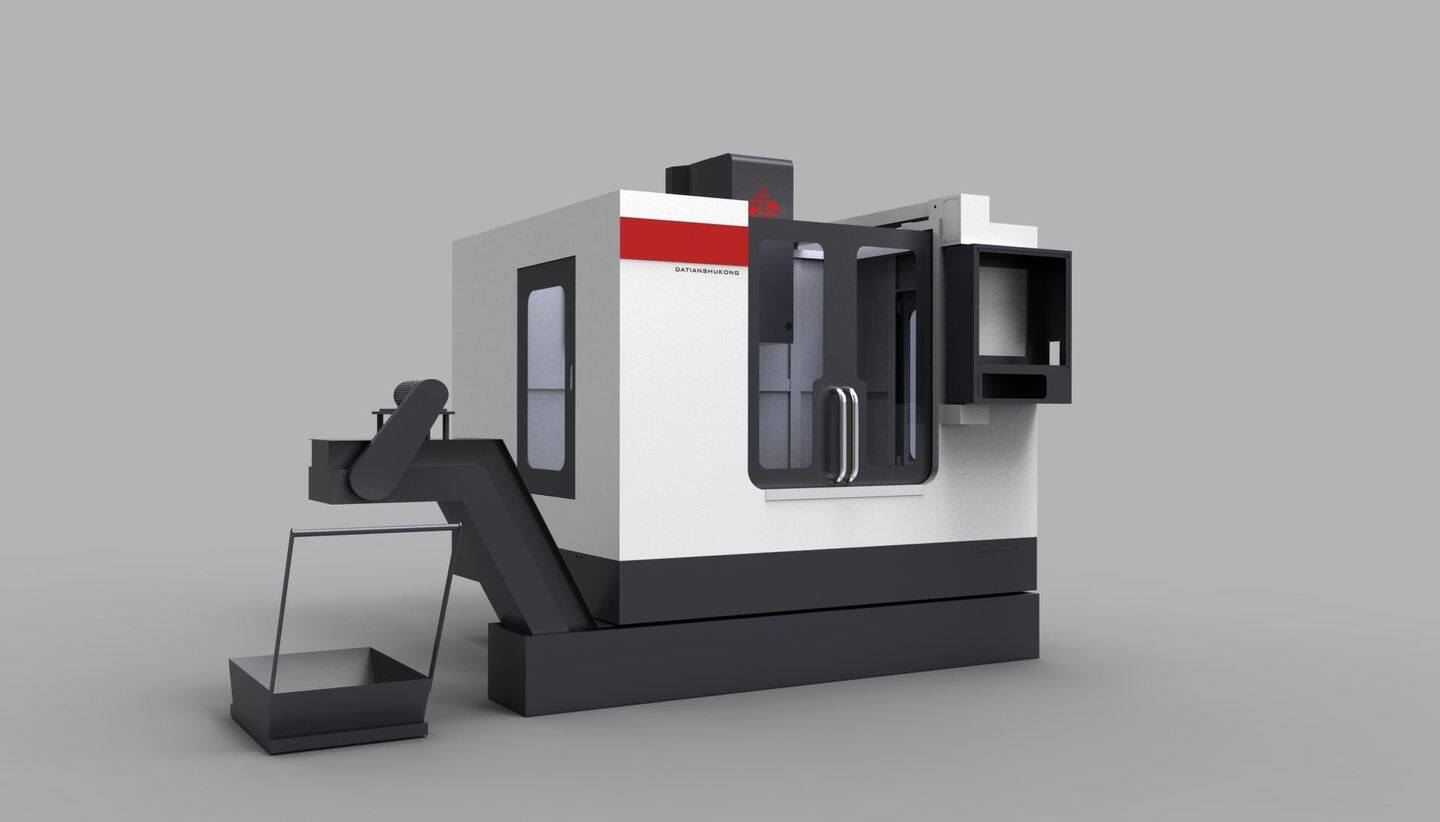

9 Advantages of CNC Machining

With the development of the computer, digital system has penetrated every industry. Manufacturing can be said to be the same. Nowadays, the advantages of CNC processing are welcomed by many industries in its manufacturing and manufacturing applications.

Advantages of CNC processing

- Safety

The operator of the CNC machine tool is safely separated from all sharp parts through a special protective structure. He can still see what happens on the machine through the glass, but he doesn't need to go anywhere near the mill or spindle. The operator does not have to touch the coolant. Depending on the material, some liquids may be harmful to human skin.

- Save labor cost

Now, conventional machine tools need constant attention. This means that each worker can only work on one machine tool. When the CNC era came, the situation changed dramatically. It takes at least half an hour for most parts to be processed during each installation. But CNC machine tools are completed by cutting parts themselves. No need to touch anything. The tool will move automatically, and the operator only needs to check whether there is an error in the program or setting. Having said that, CNC operators found that they had a lot of free time. This time can be used for other machine tools. Therefore, one operator, many machine tools. This means you can save manpower.

- Minimum setting error

Traditional machine tools rely on the operator's proficiency in measuring tools, and excellent workers can ensure high-precision assembly of parts. Many CNC systems use special coordinate measurement probes. It is usually installed on the spindle as a tool, and the probe contacts the fixed part to determine its position. Then, determine the zero point of the coordinate system to minimize the setting error.

- Excellent machine tool status monitoring

The operator must identify machining faults and cutting tools, and his decision may not be optimal. Modern CNC machining centers are packed with different sensors. You can monitor torque, temperature, tool life and other factors while machining the workpiece. Based on this information, you can improve the process in real time. For example, you see that the temperature is too high. Higher temperature means tool wear, poor metal properties, etc. You can reduce the feed rate or increase the coolant pressure to solve this problem. Although many people say that machining is the most widely used manufacturing method today. Every industry uses machining to some extent.

- Stable accuracy

What is more stable than a proven computer program? The movement of the instrument is always the same, because its accuracy only depends on the accuracy of the stepping motor.

- Fewer test runs

Traditional machining inevitably has some test parts. Workers must get used to this technology. When doing the first part and testing new technology, he will definitely miss something. CNC system has a way to avoid test run. They use a visualization system that allows the operator to view the inventory after all the tools have passed.

- Complex surface processing is easier

For traditional machining, it is almost impossible to manufacture complex surfaces with high precision. It requires a lot of physical labor. Cam system can automatically form a tool path on any surface. You don't need to make any efforts at all. This is one of the biggest advantages of modern CNC processing technology.

- Higher cutting parameters

Only due to the closed cutting area can high-speed machining be carried out. At this speed, the chip flies high speed all over the place. There is a coolant spray after the chip because when it comes to high-speed machining, the coolant is applied under high pressure. When the speed reaches 10000 rpm or higher, manual operation is impossible. The cutting speed is high, so it is very important to keep the feed speed and chip width stable to prevent vibration. Manual implementation cannot be difficult.

- Higher processing flexibility

The traditional method is that the milling machine processes the groove or plane, the lathe processes the cylinder and taper, and the drilling machine process the hole. CNC machining can combine all the above contents into one machine tool. Because the tool path can be programmed, you can copy any motion on any machine tool. Therefore, we have milling centers that can manufacture cylindrical parts and lathes that can mill grooves. All of these can reduce the set of parts.

Make a purchase of quick cnc machining, cheap cnc machining, cnc machining inc from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.